Skip to content

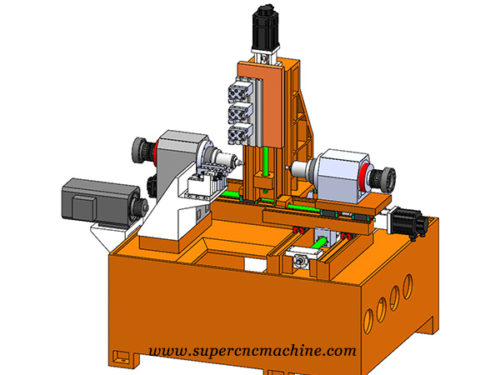

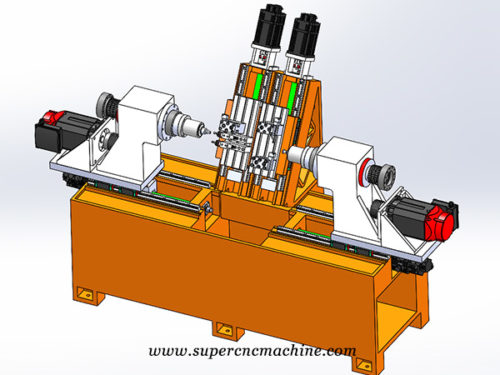

Double Spindle CNC Lathe

Home/Double Spindle CNC Lathe

-

- High efficiency: short machining cycle, reducing non-cutting time; (the second spindle can realize complete synchronous turning, and can quickly transfer workpieces during the machining process through program control, so as to shorten the cycle time).

- High precision: Equipped with the second spindle and the second tool post to realize the rotating docking of the workpiece and secondary processing, which reduces the clamping time and improves the coaxiality of the machine tool;

- High space efficiency: the smaller space plays the biggest role, which is convenient for personnel operation and automatic loading and unloading;

- X/Z axis adopts three-point positioning ball screw, which is easy to install, improves the service life of the bearing, reduces the thermal error of the machine tool, has high positioning accuracy, good stability and easy maintenance;

- X/Z axis adopts linear guide rail design, which increases the higher dynamic and static load of the guide rail, improves the rigidity of the machine tool, has high positioning accuracy, good stability and easy maintenance;

- The spindle unit or electric spindle can be customized to ensure that the machine tool has better rigidity during fast operation;

- The machine tool adopts an integral casting bed with good stability. The bed can be clamped and processed at one time, with high precision and durability.