CNC Machine Tools: Revolutionizing Precision Machining

Program Editing and Input for CNC Lathes

Before any cutting begins, it’s essential to analyze and compile the machining program for the workpiece. For complex or extensive programs, it’s more efficient to use a separate programming machine or computer instead of the CNC lathe’s control panel. This way, the program can be transferred into the CNC system via external storage or a communication interface, ensuring that the CNC lathe or CNC turning center is available for actual machining work, thus minimizing downtime.

Initiating the CNC Turning Center

Booting Up the System

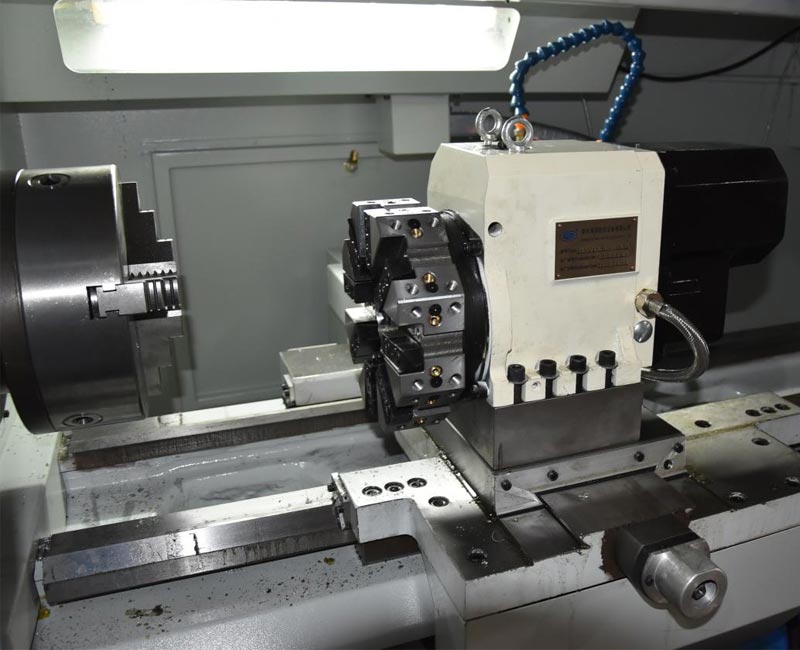

To start the precision machining process, the main power of the CNC machine tools is engaged first. This is followed by starting the CNC system, which brings the CNC lathe to life. The system’s CRT or display unit will show all relevant information, including the status of clamps and other auxiliary devices.

Setting a Fixed Reference Point

An essential step in CNC machining is establishing a fixed reference point. This serves as the movement datum for the machine tool’s coordinates, ensuring accuracy and repeatability in the CNC turning center’s operations.

Loading and Executing the Machining Program

Input and Recall of the Program

Depending on the medium of the program—tape, disk, or digital storage—it can be input using a tape reader, programming machine, or through serial communication. In the case of straightforward programs, direct input is possible on the CNC control panel via the keyboard. For more granular control, the MDI (Manual Data Input) mode allows for segment-by-segment programming. Before the actual machining, it is crucial to input the workpiece’s origin, tool parameters, offsets, and various compensation values into the CNC machine tools’ system.

By integrating CNC machine tools such as CNC lathes and turning centers into manufacturing processes, workshops can significantly enhance efficiency and reduce manual labor. These tools have become indispensable in the field of precision machining, offering the accuracy and consistency required for today’s high-demand manufacturing environments.

Program Editing and Debugging in CNC Machine Tools

Program Editing

When a program requires modifications, ensure the machine’s mode selection switch is set to the editing position. Utilizing the edit functions allows for the addition, deletion, and modification of program segments as necessary.

Program Inspection and Debugging

Verifying the Program

Begin by locking the machine to prevent any movement and then run the system in a non-physical mode to check the program. Any errors identified during this step would require returning to the editing phase for corrections.

Workpiece Installation and Machine Alignment

Setting Up the Workpiece

The next phase involves the installation and precise alignment of the workpiece on the CNC machine. Establish a clear benchmark using manual incremental, continuous, or handwheel movements of the machine. Define the program’s starting point and set the tool reference accordingly.

Executing the Machining Process

Starting the Axes for Continuous Machining

For continuous machining, operate from the program stored in memory. Adjust the feed rate as necessary with the feed rate control, and use the feed hold button to pause and observe the machining process or conduct manual inspections. To resume, simply press the cycle start button. Before full-scale processing, recheck everything to ensure accuracy. For visual verification on milled curved planes, a pencil may replace the tool to sketch the workpiece’s outline on paper, or utilize the system’s tool path simulation function if available.

System Shutdown

Powering Down

After completing the machining tasks and before shutting down the power, it’s crucial to review the status of the CNC machine and the position of its components. Power down the machine first, followed by the system, and finally, turn off the main power to ensure a safe and proper shutdown.