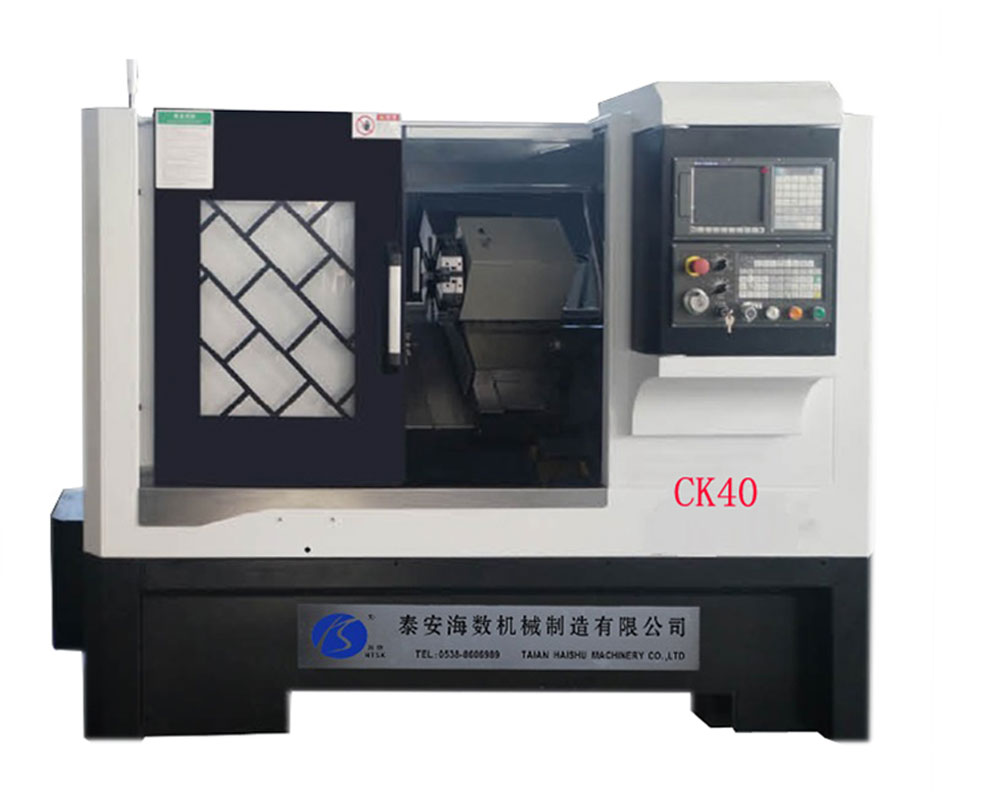

Slant Bed CNC Turning Center CK4045 is controlled by a computer numerical control. The programmer can manually design a part or tool path as well. The resulting coded computer file is then uploaded to the CNC machine, and the machine will then automatically produce the desired parts for which was programmed to design. These lathes are designed in a variety of ways, can customize the configuration.CNC turning center is suitable for medium and small batch machining of sophisticated and complex rotary parts. The CNC lathe machine is equipped with power tools. In addition to the turning function, the CNC lathe has axial, radial drilling, tapping, and milling functions.

The American customer needed a slant bed CNC Lathe Machine. He checked the CK4030 and thought the slant bed lathe is the one they need. Later he sent us his workpiece drawings directly. The CK4030 CNC lathe is too small because they need a customized powerhead. We chose Slant Bed CNC Turning Center CK4045 for him. After confirming the detailed quotation of the Slant Bed CNC lathe. He also was very agreed with us and requested the customized configuration. Our engineers have designed renderings for customers, and they were very satisfied after checking. We had a video connection to have a meeting to confirm all the details, and then arranged the payment of the deposit.

When the Slant Bed CNC Turning Center CK4045 completed, We sent him the Slant Bed CNC Lathe Machine operation video and We have appointed a time for the video connection to view the test machine process online, which was very appreciated by the customer.

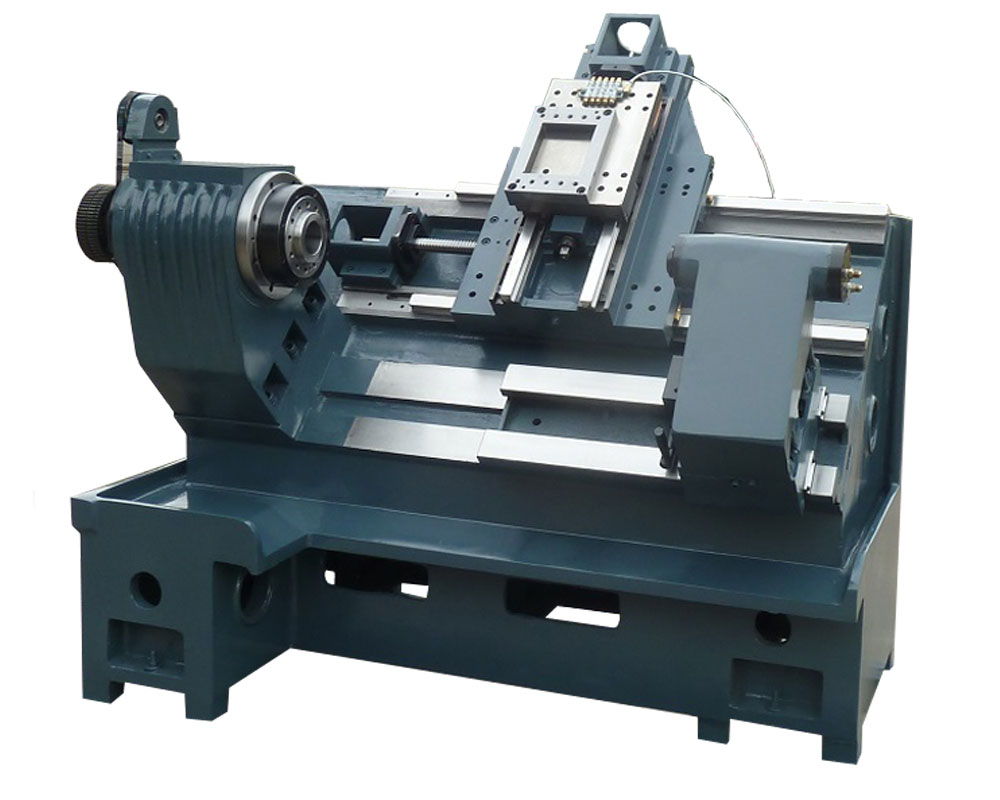

Slant Bed CNC Turning Center CK4045 Specifications

| Maximum turning diameter of the bed | 400 | 400 |

| Maximum turning diameter on the pallet | 150 | 150 |

| Spindle head form | Spindle unit | Spindle unit |

| Spindle through hole diameter | 49 | 49 |

| Maximum spindle speed | 4000 | 4000 |

| X fast-moving speed | 20 | 20 |

| Z fast-moving speed | 20 | 20 |

| X/Z axis repeat positioning accuracy | 0.003 | 0.003 |

| Processing accuracy | 0.01 | 0.01 |

| X-axis travel | 80(Bidirectional) | 80(Bidirectional) |

| Z-axis travel | 480 | 480 |

| Rail form | Linear rail | Linear rail |

| Guide rail (Taiwan HIWIN) X direction (roller) | RGH30CA2R880ZAHII | RGH30CA2R880ZAHII |

| Guide rail (Taiwan HIWIN) Z direction (roller) | RGH35CA2R950ZAHII | RGH35CA2R950ZAHII |

| X-direction screw (Jiangsu Qijian) | 3208*784 | 3208*784 |

| Z-direction screw (Jiangsu Qijian) | 4010*904 | 4010*904 |

| Machine weight | 2000 | 2000 |

| Machine size | 1830*1500*1750 | 1830*1500*1750 |

Slant Bed CNC Turning Center CK4045 Configuration

- GSK980TC3 system bus system

- Row Tool holder

- Hydraulic collet

- 4kw servo main motor

- Spindle unit

- X / Z Taiwan Rail

About HAISHU Machinery

Our company Taian Haishu Machinery Co., Ltd provide high-precision, high-speed and high-rigidity CNC machines and related parts.In the face of rapidly changing technologies, we recognize that we need to improve overall performance even further. That is why we are focusing most of our efforts on research and development. Now we have our system, our software, our brand and patent. Looking ahead, we still take on board direct feedback from customers and anticipate their needs, so that we can maintain our focus on product development, with an emphasis on CNC lathes, CNC milling machine, CNC machining center, Slant Bed CNC Turning Center , CNC tool grinding machine, CNC pipe threading lathe, wheel cnc lathe, stone CNC machine and other high-precision processing machinery, and continue providing products that guarantee customer satisfaction.We hope we can continue to rely on your support in the future.