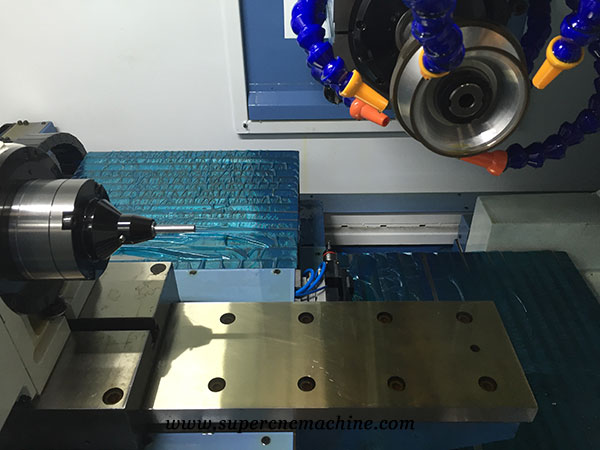

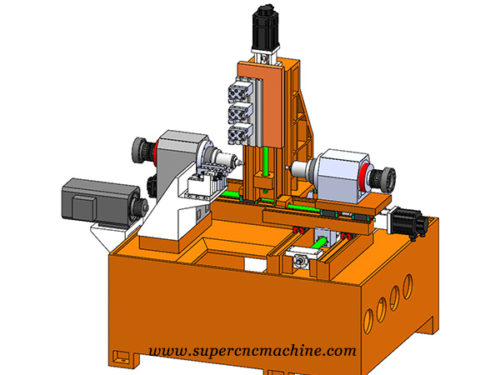

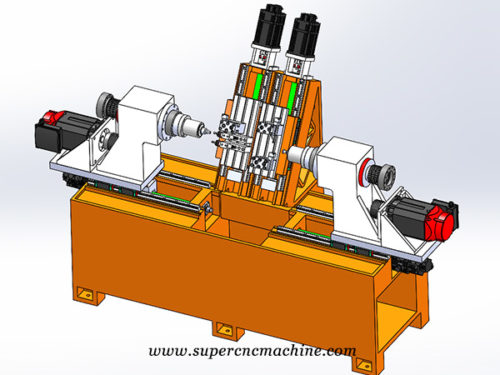

CNC Tool Grinder (also called CNC Tool Grinding Machine,CNC Tool Grinding Lathe) VIK-5C designed and manufactured by HAISHU Machinery is the high quality, high performance 5 axis CNC machine for tool grinding applications. HAISHU brand 5 Axis CNC Tool Grinder VIK-5C is the powerful CNC machine tool to grind the widest range of tools or cutters from a simple 5mm endmill to a 450mm long drill or a 400mm diameter face cutter. The rigid machine design, strict manufacturing process quality control, high precision spindle, powerful CNC system and ensure any grinding operations completed with ease.

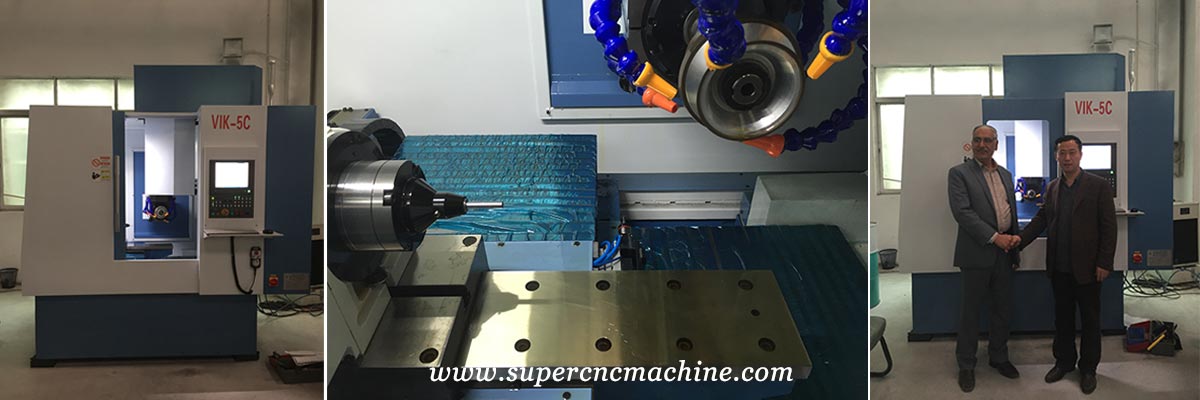

High Quality 5 Axis CNC Tool Grinder VIK-5C

Description

CNC Tool Grinder (also called CNC Tool Grinding Machine,CNC Tool Grinding Lathe) VIK-5C designed and manufactured by HAISHU Machinery is the high quality, high performance 5 axis CNC machine for tool grinding applications. HAISHU brand 5 Axis CNC Tool Grinder VIK-5C is the powerful CNC machine tool to grind the widest range of tools or cutters from a simple 5mm endmill to a 450mm long drill or a 400mm diameter face cutter. The rigid CNC tool grinder design, strict manufacturing process quality control, high precision spindle, powerful CNC system can ensure any grinding operations completed with ease.

High Quality 5 Axis CNC Tool Grinder VIK-5C

5 Axis CNC Tool Grinder VIK-5C Specifications

| No | Item | Detail | Specifications |

|---|---|---|---|

| 1 | Stroke | X – Axis | 320 mm |

| 2 | Y – Axis | 260 mm | |

| 3 | Z – Axis | 280 mm | |

| 4 | A – Axis | 360° | |

| 5 | C – Axis | 230° | |

| 6 | A Axis | Clamping Range | Φ0.3~Φ20 mm |

| 7 | Revolution Diameter | Φ320 mm | |

| 8 | Minmum index unit | 0.00001° | |

| 9 | maximum revolution speed | 30 rpm | |

| 10 | Main Spindle | Taper | 31.75/20 (grinding wheel rod) |

| 11 | Main shaft speed | 7000 rpm | |

| 12 | Power transmission | Motor Spindle | |

| 13 | Movement | Three axis rapid movement | 15/15/15 m/min |

| 14 | Minimum input unit | 0.001 mm | |

| 15 | Motor | Spindle Power | 7.5/12.5 KW |

| 16 | Shaft drive system | Variable frequency electric spindle | |

| 17 | Feed Drive System | AC Servo | |

| 18 | Lubrication | Lubrication System | 2 L |

| 19 | Air | Compressed Air Requirement | 0.6 MPa |

| 20 | Power | Power capacity | 25 KVA |

| 21 | Size | Machine Size (LWH) | 2200×1400×2400 mm |

| 22 | Weight | Machine Weight | 5500 Kg |

| 23 | Total Weight | about 6000 Kg |

5 Axis CNC Tool Grinder VIK-5C Configuration

Standard Configuration

- Basic grinding software package (milling cutter, drill, Shape tool)

- Grinding wheel and workpiece dual head system, inlet MARPOSS probe

- X, Y, Z linear axis C3 class screw rod, H level linear slide rail, direct connection drive

- X, Y, Z, A, C, five axis controlled by famous brand servo motors

- Automatic lubrication system

- Five axis hand held pulse generator

- Leakage protection function

- Grinding wheel clamping connecting component

- Pneumatic spring collet

- Spindle oil cooler

- Special toolbox for machine tools

Optional configuration

- Oil frog collector

- Circulating cooling filtration system

- Extended tool groove grinding support accessories

- Index head accessories for the top and tailstock core clamper

- Other customized fixtures, mandrel, etc

- Linear encoder

- Special tool programming module

- Special specification spring collet

- Automatic feeding and unloading system

- Inductive fire extinguisher

5 Axis CNC Tool Grinder VIK-5C Features

- Multi-functional, high stability, automation, easy to operate.

- CNC tool manufacturing system, five-axis linkage control.

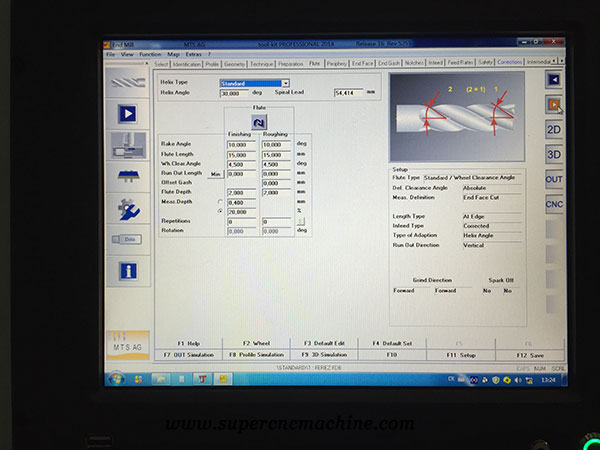

- Special tool software, 2D or 3D simulation shows the corresponding tool parameters, can be configured to professional automatic loading and unloading agencies, automatic production.

- Using high-power spindle, equipped with special oil-cooling device.

- Dynamic rigidity of the machine, with a full digital servo system, with a workpiece and wheel double probe system, the wheel shape

- Automatic measurement of dimensions and other parameters such as outside diameter helix angle during tool manufacture and grinding.

- CNC high-speed servo positioning, cylinder balance system, rapid response, balance grinding head weight and cutting load, reliable coolant supply and filtration system equipped with oil mist separation device, a comprehensive closed processing, tight seal, no leakage.

- Imported brand servo motor, linear guide, ball screw, imported bearings.

- 5 axis CNC software, flexible and strong, Machinable all kinds of ball cutter, ladder drill, reamer, forming knife, gun drill, toothed cutter, rotary cutter and other special workpiece processing.

- Special tool grinding package and automatic loading and unloading system are configured according to the special requirements of customers.

- The CNC tool grinder software with 2D and 3D demo function can display the complete machining tool shape to avoid parameter setting errors on the workpiece and machine damage and interference machine collision. The software can store hundreds of tool parameters and models without having to adjust the machine settings.

- The CNC tool grinder is simple to set parameters with less requirement for the operators.

High Quality 5 Axis CNC Tool Grinding Machine VIK-5C

About HAISHU Machinery

As the professional CNC machine designer and manufacturer, Taian Haishu Machinery Co., Ltd (Haishu Machinery) is the high-tech enterprise specialized in CNC machine development, production, sales and service since 2001. We have more than 30 professional talented CNC experts and more than 12,000 square meters manufacturing factory. More than 16 series 80 kinds of CNC machines and related parts had been manufactured to satisfy your pumping requirements. Our high quality and innovative products include CNC lathes, CNC milling machine, CNC machining center, CNC turn mill machine, CNC tool grinding machine, CNC pipe threading lathe, CNC wood lathe, stone CNC machine, CNC root canal file grinder and custom CNC equipment for special requirements.

HAISHU Machinery is not only manufacturing best quality CNC machine products but also providing custom product design, fabrication and after sale services. Welcome contact us for detailed information.