Customized CNC turning machine is a type of machine tool used for metalworking and manufacturing, primarily for rotating a workpiece and cutting its outer surface to achieve the desired shape and size. The main materials that can be processed by CNC turning machine include steel, copper, aluminum, titanium, and magnesium. The components produced by Cnc turning machines are widely used in automotive, aerospace, electrical, medical, and other equipment.

A US customer inquired about a CNC Lathe from our company. After describing their requirements, we recommended the HAISHU CK40X CNC lathe. In the quotation, we provided a detailed list of the technical parameters of this CNC lathe machine, such as the maximum turning diameter of 400mm, the maximum processing length of 350mm, and the X-axis maximum travel of 760mm. The spindle unit of this CNC lathe uses an A2-5 or A2-6 spindle unit, with a maximum speed of up to 3000 rpm. For the tool turret, we recommended a tool magazine, electric tool holder, hydraulic tool holder, and power turret. The guide rail uses Taiwan Shangyin guide rail, and we provided two options for the main motor to the customer, 7.5kw and 5.5kw. After providing the detailed quotation, the customer expressed satisfaction with our professional response. However, the customer felt that they would encounter medium to long length workpieces in future machining, but failed to provide specific requirements. As a professional manufacturer of CNC lathes, we adhere to the principle of providing customers with the most satisfactory products, and therefore recommended another lathe with a tailstock and servo hydraulic turret. The customer was very satisfied. Now, we would like to introduce this high-standard and cost-effective CNC lathe to everyone.

We provide our customers with a new customized CNC turning machine, namely model HSTC550, which adopts a Japanese-style high-low rail structure, featuring strong rigidity and high machining accuracy. For the system, we use the GSK980TDi bus absolute value system, which is an advanced CNC system with high performance, including dual-core ARM processors, a graphical interface, and user-friendly operation. It is also stable and reliable with advanced adaptive control algorithms and noise suppression technology. The system has strong openness, supporting multiple communication protocols and interfaces, which can seamlessly connect with various devices. In addition, its relatively low cost reduces customers’ expenses and improves the product’s cost-effectiveness. This system is affordable and can meet the needs of enterprises, helping to reduce machining costs.

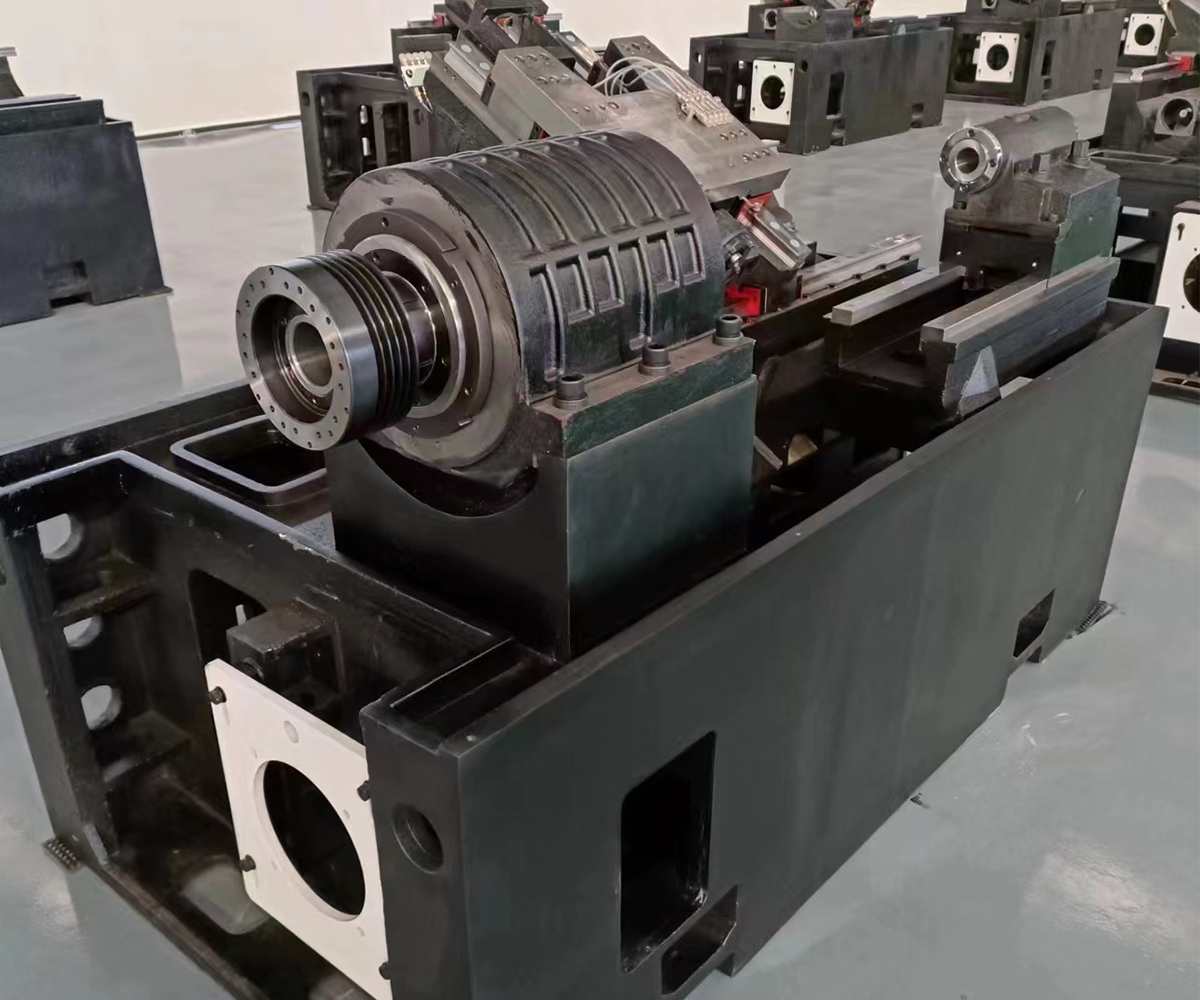

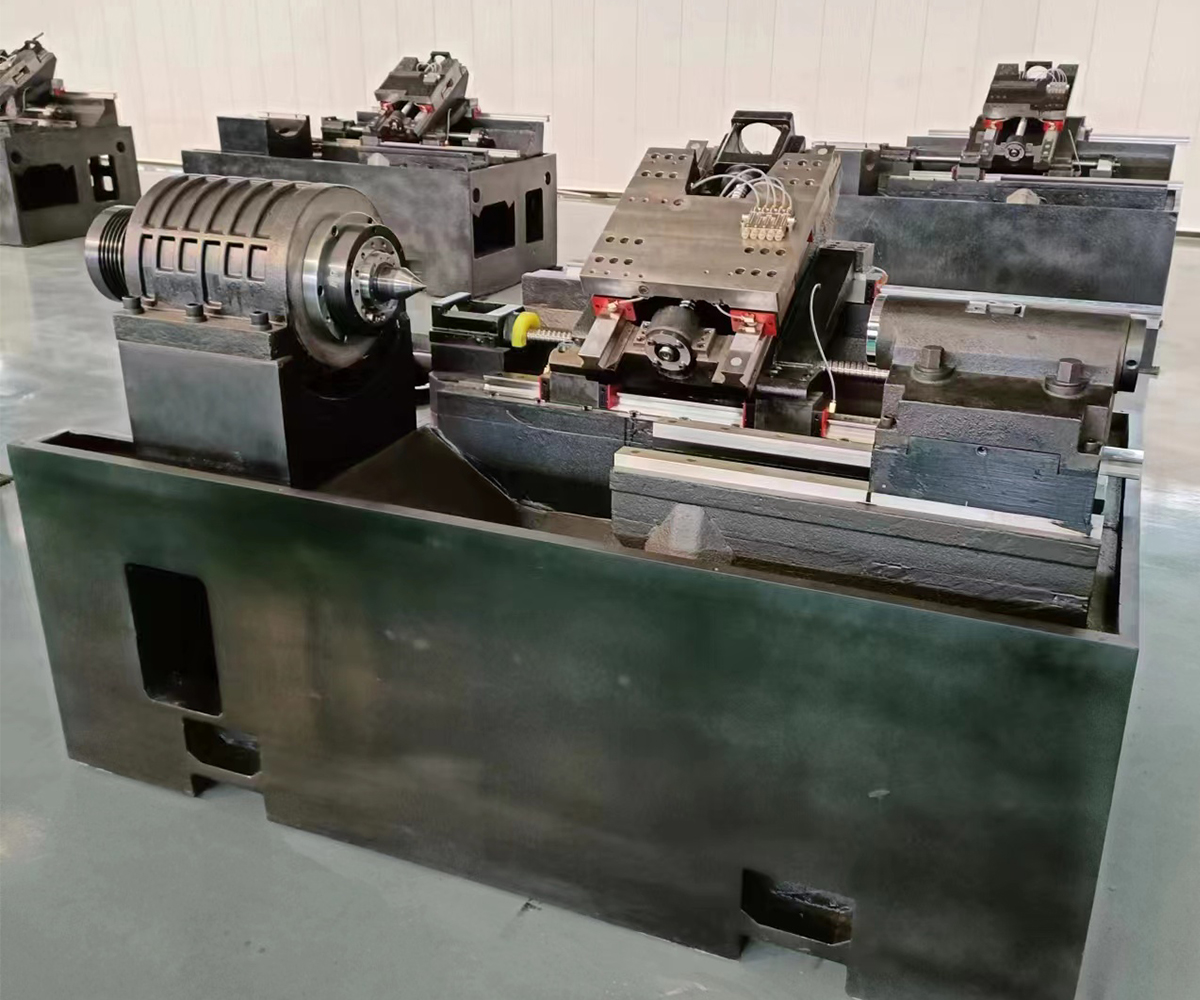

The reason why we recommend this customized CNC turning machine is because it has a machining length of up to 550mm, which is ideal for meeting our customers’ requirements. The main motor has also been increased to 11kW, and a larger A2-6 spindle unit has been directly adopted, with P4 grade spindle bearings. The X and Z axes bearings use Japanese NACHI brand, ensuring high machining accuracy. The guide rails use well-known brands such as Shangyin and THK. Additionally, we specially equipped the machine with an 8-station servo hydraulic turret, which has the characteristics of fast tool changing and can firmly lock the tool position. Even with a larger turret, the X-axis travel is still 240mm, and the Z-axis travel reaches an impressive 600mm. The machine’s swing diameter also reaches 550mm, and the spindle’s drawbar through-hole diameter is 52mm, equipped with an 8-inch hydraulic hollow chuck, providing customers with fast and stable clamping. Most importantly, the movement speed of both axes is up to 15-20m per minute. The hydraulic tailstock provides strong support for machining medium to long shafts. This customized CNC turning machines weighs nearly 4 tons and is a truly low center of gravity and high rigidity Japanese-style high-low rail structure precision customized CNC turning machines.

In terms of details, we have made significant optimizations to the HAISHU CNC lathe. The entire machine tool guide rail protective cover is made of stainless steel, which effectively protects the lead screw guide rail and is not easily corroded by cutting fluid. For the water pump, we use a high-pressure water pump to provide greater water pressure for cooling, which can maximize the reduction of tool temperature and flush away machining debris. Due to the large size of this CNC lathe, we also provide customers with an automatic chip conveyor to facilitate cleaning of iron chips. The customer can manually or automatically turn it on, eliminating the worry and trouble of manually cleaning iron chips. To enable customers to monitor the working status of the CNC lathe at all times, we also added a machine tool working indicator light, allowing customers to observe the working status of the CNC lathe in real-time. We also installed a handheld pulse generator for customers to easily control the movement of the X and Z axes at will. The issue of water entering the turret is also a concern for many customers, so we added a stainless steel protective cover to the 8-station servo hydraulic turret to enhance its protection and aesthetics. Details are essential. Due to the through-hole drawbar of the hydraulic chuck, we also added a water collection device behind the rotary cylinder to effectively prevent cutting fluid from dripping onto the motor or other electrical components. Our American customers highly praised and appreciated our quotation, technical parameters, configuration, details, and other aspects.

After the deal was closed for this customized CNC turning machine, there was a small episode where our American customer sent us a request to change the working voltage, even though we had already specified the working voltage in the agreement. However, in line with our principle of being responsible to our customers and providing excellent customer service, HAISHU modified the working plan promptly to meet the customer’s temporary request. In fact, HAISHU CNC turning machines also provide customization services. We suggested that the customer add a fully automatic servo feeder and provided a working video, but in the end, the customer said they didn’t need this function for the time being, so we did not provide the feeder function. This exhibits the professionalism and quality of HAISHU CNC turning machines, which allows customers to recognize us as a professional CNC turning machines manufacturer.

After completing this CNC turning machine, we provided the customer with a machining video, which also served as the acceptance video. In the video, we demonstrated CNC machining processes such as arc, chamfer, thread, and groove, fully showcasing the advantages of HAISHUcustomized CNC turning machines and earning the customer’s trust in our capabilities. After acceptance, we also recorded videos on how to connect to power, various precautions, and maintenance guide for the CNC turning machines, providing comprehensive guidance for the customer. Finally, the American customer had more confidence in and gave recognition to our HAISHU CNC turning machines. We hope that our CNC turning machines can better serve customers and create economic value.

The packaging process before shipping to our customers also reflects our corporate culture.

HAISHU CNC turning machines are packed with standard export packaging and reinforced bolts, emphasizing safety and environmental requirements. We mark our CNC turning machines with product labels that indicate volume, weight, and loading positions for forklifts to ensure safe and efficient unloading. Our attention to detail and professionalism in packaging and exporting customized CNC turning machine showcases the expertise of HAISHU in this field.

To ensure the safety of CNC turning machines during transportation, we use reinforced bolts and environmentally friendly materials in our packaging, adhering to international standards and regulations.

In addition, we label our CNC turning machines with product information and loading positions for forklifts, allowing for safe and secure unloading and minimizing the risk of damage or loss.

At HAISHU, we prioritize both the quality and performance of our CNC turning machines, as well as the details and professionalism in their packaging and exporting. We are committed to ensuring that our CNC turning machines arrive in the best possible condition for our customers.

As a CNC turning machines manufacturer, HAISHU deeply understands the needs and expectations of our customers. Therefore, at every stage of our process, we strive to provide high-quality services that showcase our professionalism and patience.

During the consultation and quotation stage, we patiently listen to our customers’ requirements and provide tailored solutions that meet their needs and circumstances, ensuring that they receive the most suitable CNC turning machines and plans. In the transaction stage, we offer our customers more discounts and benefits as much as possible, demonstrating our honesty and sincerity.

In the production planning stage, we tailor our production plans according to our customers’ needs and circumstances, ensuring on-time delivery and allowing our customers to receive their CNC turning machines as soon as possible. During the inspection stage, we strictly adhere to national standards and requirements to ensure that the quality and performance of our CNC turning machines meet our customers’ needs and expectations.

In the shipping stage, we use standard export packaging, reinforced bolts, and pay attention to the safety and environmental requirements of CNC turning machines, providing our customers with safe and reliable services. We emphasize our professionalism and patience at every stage to ensure that our customers receive high-quality services and products.

In summary, HAISHU showcases our professionalism and patience as a CNC turning machines manufacturer at every stage of our process, including consultation, quotation, transaction, production planning, inspection, and shipping. We will continue to uphold this philosophy, continuously improve our service level and product quality, and create greater value for our customers.

If you have any questions about CNC turning machines or need to learn more detailed information, we welcome you to visit HAISHU’s official website. As a professional CNC turning machines manufacturer, our website provides comprehensive product information, technical parameters, application cases, and other detailed materials to help customers better understand our products and services.

On HAISHU’s official website, you can easily learn about various detailed information of our CNC turning machines, including product types, performance, technical parameters, etc. Our product types cover various CNC turning machines types, including vertical CNC turning machines, horizontal CNC turning machines, slant bed CNC turning machines, gantry CNC turning machines, etc., to meet the needs of different customers. At the same time, our website also provides rich technical parameters and application cases, allowing customers to better understand the performance and application scope of our CNC turning machines.

In addition to product information and technical parameters, HAISHU’s official website also provides various services and supports, including after-sales service, technical support, training support, etc. We are committed to providing customers with comprehensive services and supports to help them better use and maintain our CNC turning machines products.

Finally, we also provide online consultation and message board services, allowing customers to contact us at any time and learn more detailed information about our CNC turning machines. We look forward to working with you and providing you with high-quality CNC turning machines products and services.