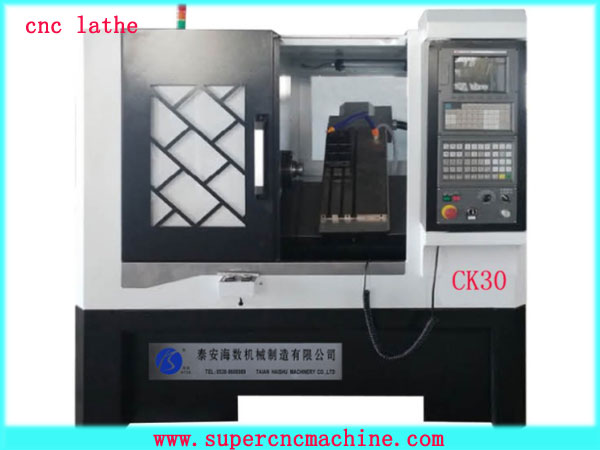

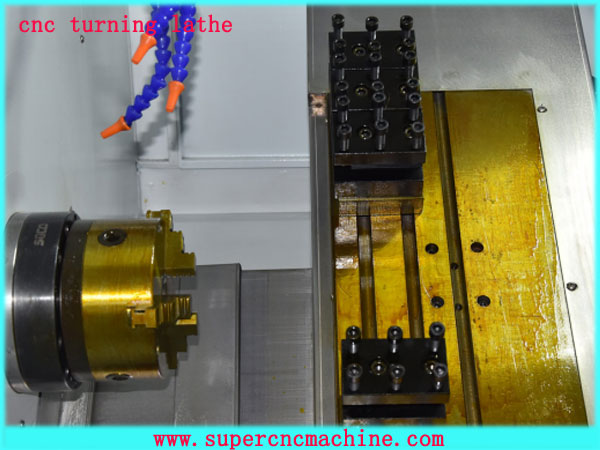

CNC turning Lathe machine CK4030 is designed with a low gravity center and the short-distance structure of the main shaft which reduce the loading and unloading strength of the workpiece. The design of the cut-type knife arrangement and the fast and accurate tool exchange saves processing time and reduces maintenance costs. The guide surface of the bed is inclined at 45 degrees, with a large load-bearing cross-section, which can ensure high-precision cutting. The CNC Lathe can automatically complete the internal and external cylindrical surface, conical surface, arc surface, end surface, grooving, chamfering, and other processes for various shaft parts.

Our Russian customer needed CNC lathe with a slant bed. After confirming his workpiece size, and we chose CNC turning Lathe machine CK4030 for him. He also requested 4 pieces of row tools. Our engineer made renderings for him according to his requirements. He was very satisfied and requested to send the PI to him as soon as possible. A few days later he arranged the payment of a deposit.

When the CNC turning Lathe machine CK4030 completed, we sent him the Slant Bed CNC Lathe Machine operate video and the completed workpieces. He was very satisfied and paid the balance soon.

CNC Turning Lathe Machine Ck4030 Specifications

| Item | Unit | Specifications |

|---|---|---|

| The maximum turning diameter of the bed | mm | 400 |

| Maximum turning diameter on a pallet | mm | 150 |

| Maximum processing length | mm | 300 |

| Spindle head form | Spindle unit | |

| Spindle through hole diameter | mm | 49 |

| Rail width | mm | 250 |

| The total length of the guide rail | mm | 640 |

| X/Z axis repeat positioning accuracy | mm | 0.01 |

| X fast-moving speed | m | 12 |

| Z fast-moving speed | m | 15 |

| Maximum spindle speed | rpm | 4500 |

| Machine tool dimensions (L × W × H) | mm | 1700*1200*1600 |

| Machine weight | kg | 1400 |

CNC Turning Lathe Machine Ck4030 Configuration

- GSK980TC3 system bus system

- Row Tool holder

- Hydraulic collet

- 4kw servo main motor

- Spindle unit

- X / Z Taiwan Rail

About HAISHU Machinery

Taian Haishu Machinery Co., Ltd provides high-precision, high-speed, and high-rigidity CNC machines and related parts. Our company has its own R&D team. Through the continuous introduction of advanced technologies and human resources at home and abroad, it has accumulated a lot of engineering experience in the CNC machine tool manufacturing industry and process. It has a design and manufacturing technology that is synchronized with the domestic CNC machine tool industry. Patent. We are firmly guided by “provide customers with valuable products” and provide customers with a full range of services before, during, and after-sales. Looking ahead, we still take on board direct feedback from customers and anticipate their needs, so that we can maintain our focus on product development, with an emphasis on CNC lathes, CNC milling machine, CNC machining center, CNC turning Lathe machine, CNC tool grinding machine, CNC pipe threading lathe, wheel CNC lathe, stone CNC machine, and other high-precision processing machinery, and continue providing products that guarantee customer satisfaction. We hope we can continue to rely on your support in the future.