Description

HSTC550 horizontal slant bed lathe is a specialized lathe machine designed for machining cylindrical workpieces. What sets it apart is its slanted bed design, which offers a more compact footprint compared to traditional horizontal lathes. This makes it an ideal choice for environments with limited space.

The slant bed lathe design provides several advantages. It allows for improved chip removal, as chips can easily fall away from the workpiece due to gravity, resulting in enhanced machining efficiency. Additionally, the slanted bed design often offers better rigidity, leading to improved machining accuracy and reduced vibrations during cutting operations.

HAOSHU Machinery is a professional CNC lathe manufacturer and supplier, providing a wide range of custom CNC lathes with various specifications. Their commitment to quality and competitive factory prices ensures customers can find the right CNC lathe to meet their specific needs.

1.What Is Horizontal Slant Bed Lathe?

The horizontal slant bed lathe is a specialized type of lathe machine designed for machining cylindrical workpieces. Unlike traditional horizontal lathes with a flat bed, the slant bed lathe features an angled or slanted bed design. This compact and optimized design offers several advantages.

The slanted bed allows for efficient chip removal, as chips can easily fall away from the workpiece due to gravity. This leads to improved machining efficiency and surface finish.

Compared to traditional horizontal lathes, the slanted bed design provides better rigidity, resulting in enhanced machining accuracy and reduced vibrations during cutting operations.

The ergonomic advantages of the slanted bed design include improved operator access to the workpiece and cutting tools, facilitating easier setup and monitoring of machining processes.

Slant bed lathes have a more compact footprint, making them suitable for environments with space limitations.

2. Technical Data Of HSTC550 Horizontal Slant Bed Lathe

| 1 |

Item |

Unit |

Specification |

Remark |

| 2 |

Rotation diameter |

mm |

550 |

|

| 3 |

X-axis travel |

mm |

240 |

|

| 4 |

Z-axis travel |

mm |

600 |

|

| 5 |

Maximum cutting diameter |

mm |

420 |

|

| 6 |

Maximum processing length |

mm |

550 |

|

| 7 |

Standard processing diameter |

mm |

280 |

|

| 8 |

Spindle form |

|

A2-6 |

|

| 9 |

Draw tube through hole |

mm |

52 |

|

| 10 |

Spindle through hole |

mm |

62 |

|

| 11 |

Spindle speed |

r/min |

50-3000 |

Low center of gravity and high rigidity |

| 12 |

Chuck diameter |

Inch/mm |

8寸/200 |

hollow |

| 13 |

X, Z axis repeatability |

mm |

±0.003 |

|

| 14 |

X, Z axis positioning accuracy |

mm |

0.005 |

|

| 15 |

X-axis rapid movement |

m/min |

15-25e |

Heavy preloaded roller guides |

| 16 |

Z-axis rapid movement |

m/min |

15-25 |

Heavy preloaded roller guides |

| 17 |

Tool holder type / cutter disc diameter |

–/mm |

330/340/380 |

80/100 center height 8/12 workstations |

| 18 |

Tailstock travel |

mm |

300 |

|

| 19 |

Tailstock sleeve travel |

mm |

100 |

|

| 20 |

Tailstock sleeve taper |

MT |

MT5# |

|

| 21 |

Tool size |

mm |

25*25 |

Comes standard with 1 square tool holder |

| 22 |

Boring bar diameter |

mm |

32 |

Comes standard with 3 round tool holders |

| 23 |

Machine tool gross weight |

Kg |

3700 |

Integrated bed water tank |

| 24 |

Machine size length/width/height |

mm |

2400/1600/1750 |

|

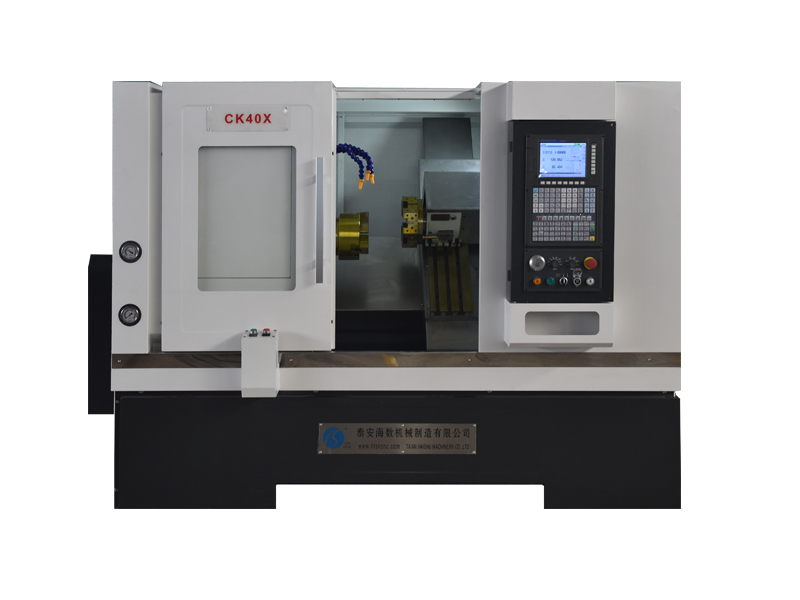

3. What Is HSTC550 Horizontal Slant Bed Lathe?

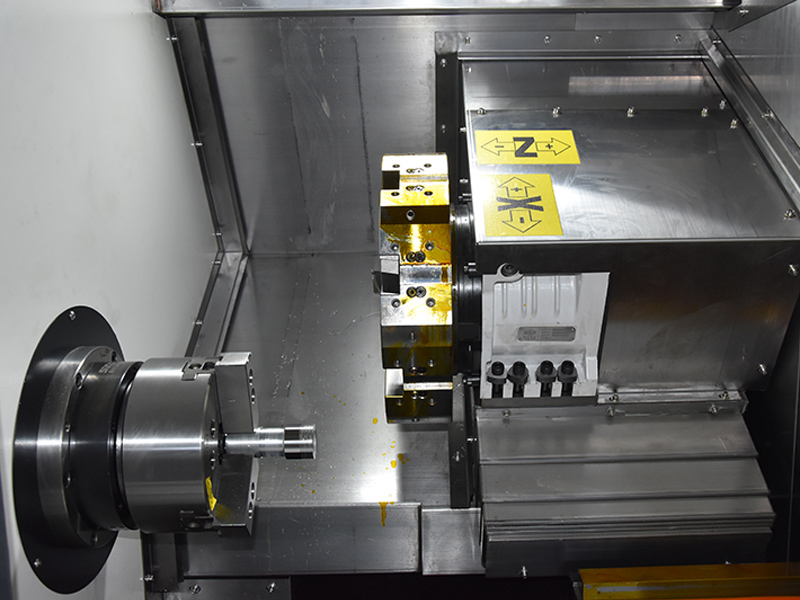

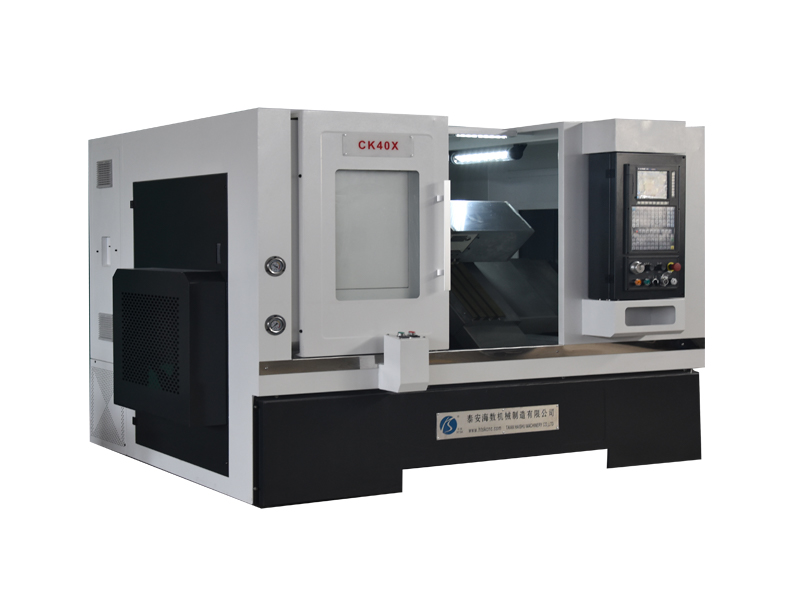

The HSTC550 Horizontal Slant Bed Lathe, manufactured by HAISHU Machinery, is a CNC multitasking horizontal turning center that combines a proven machine design with advanced control and manufacturing technology. This lathe features an inclined rail turret and is equipped with the GSK980tdi CNC system, which supports multi-functional processing capabilities, including macro programs, arcs, threads, chamfers, and other complex operations. The HSTC550 aims to help manufacturers achieve faster and more efficient part turning, ultimately increasing profitability.

The HSTC550 Horizontal Slant Bed Lathe offers reliability and performance, making it a preferred choice for demanding job shops and in-house productions. Its heavy cutting spindle and rigid machine structure contribute to higher machining efficiency, improved surface finish, and longer tool life. These factors result in increased productivity and profitability for manufacturers. By upgrading to the HSTC550, companies can enhance their global competitiveness and stay ahead in the market.

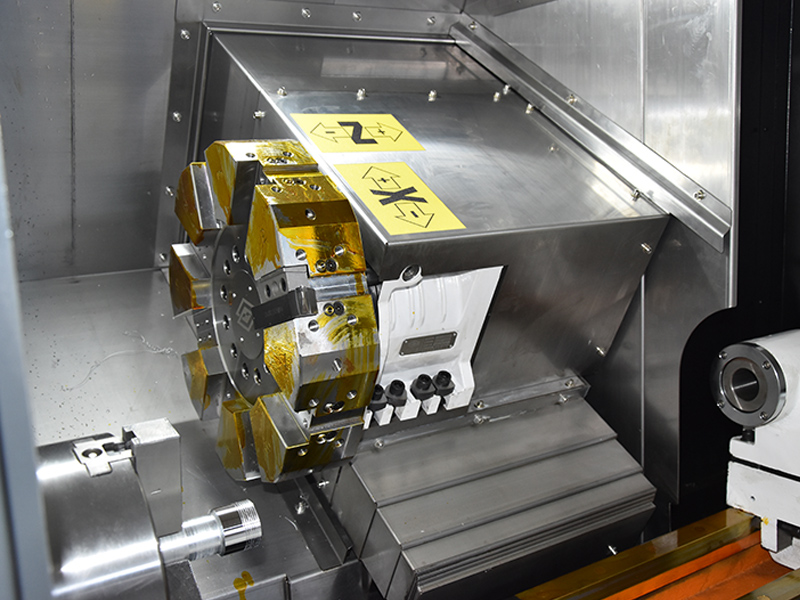

This lathe is equipped with both a servo hydraulic turret and a power turret, enabling multi-functional processing capabilities. It can perform turning and milling combined processing, as well as drilling, tapping, and other operations. The enlarged hydraulic chuck allows for the clamping of large workpieces, accommodating a wide range of part sizes. The tailstock can be either hydraulic or programmable, providing options for automatic clamping of long-axis workpieces. Additionally, the HSTC550 is compatible with robotic systems and can be integrated into production line automation, allowing for further upgrades and enhanced efficiency.

The HSTC550 Horizontal Slant Bed Lathe offers manufacturers the flexibility and versatility needed to handle various machining tasks. Its advanced features, such as the GSK980tdi CNC system, servo hydraulic turret, and power turret, enable efficient and accurate processing of complex parts. The machine’s robust construction ensures stability and precision during operation, resulting in high-quality finished products.

The HSTC550 Horizontal Slant Bed Lathe by HAISHU Machinery is a reliable and high-performance CNC turning center. Its advanced features, multi-functional processing capabilities, and compatibility with automation systems make it a valuable asset for manufacturers looking to improve productivity, surface finish, and tool life. By investing in the HSTC550, companies can elevate their competitiveness in the global market and achieve greater profitability.

4. What Are The Features of HSTC550 Slant Bed CNC Lathe?

the HSTC550 Horizontal Slant Bed Lathe offers a combination of advanced control system, robust construction, large turning capacities, precision spindle, high torque motors, superior chip removal, and customization options. These features make it a reliable and cost-effective choice for various machining applications. These features include:

4.1 Famous High-End CNC Control System

The lathe is equipped with a renowned CNC control system that ensures precise and efficient machining operations.

4.2 Robust and Compact CNC Lathe Bed

The lathe bed is designed to be robust and compact, providing stability and rigidity during machining processes.

4.3 Large Turning Capacities

The HSTC550 offers a maximum turning diameter of up to 420mm and a maximum turning length of up to 550mm, enabling the machining of a wide range of workpiece sizes.

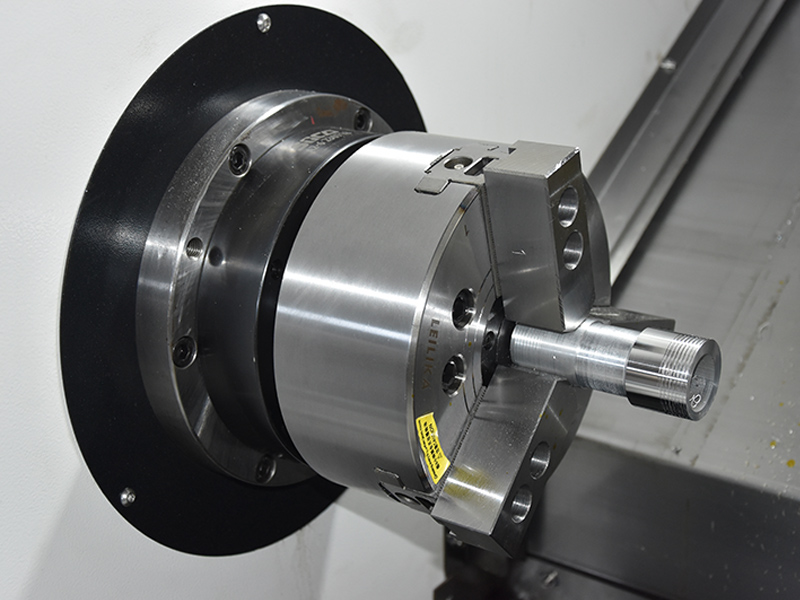

4.4 Symmetrically Designed Reinforced Headstock

The headstock of the lathe is symmetrically designed and reinforced, enhancing its stability and minimizing vibration during high-speed operations.

4.5 High Precision Spindle

The lathe features a high precision spindle with dual-roller bearings and self-alignment angular bearings, ensuring accurate and smooth rotation.

4.6 High Torque Spindle and Axis Motors

The spindle and axis motors of the HSTC550 provide high torque, allowing for efficient cutting and improved performance during heavy-duty machining.

4.7 Superior Chip Removal Performance

The lathe is designed to provide superior chip removal performance, ensuring effective evacuation of chips and debris from the work area, thereby enhancing machining efficiency.

4.8 OEM/ODM Availability

HAISHU Machinery offers OEM and ODM services, allowing for customization and tailored solutions to meet specific customer requirements.

4.9 Best Factory Price

The HSTC550 is available at a competitive factory price, providing excellent value for its features and capabilities.

5. What Are HSTC550 Slant Bed CNC Lathe Used For?

The STC550 horizontal slant bed lathe, designed by HAISHU Machinery, features a straight-line tool holder, making it highly suitable for processing small and precision workpieces. This lathe finds its primary applications in automobile manufacturing and the production of small automobile parts, including metal plugs. It is also widely utilized in the aerospace field for aviation plugs, as well as in medical equipment, mold manufacturing, the electronic industry, optical equipment, metal processing, and other related fields.

The STC550 lathe’s straight-line tool holder offers enhanced precision and stability during machining operations, making it ideal for intricate and delicate workpieces. Its design facilitates efficient processing of small components while ensuring high accuracy and excellent surface finish.

In the automobile manufacturing sector, the STC550 is particularly valuable for producing small automobile parts, such as metal plugs. Its capabilities allow for the efficient production of these components, meeting the industry’s stringent requirements for precision and quality.

In aerospace applications, the lathe is utilized for machining aviation plugs, which are critical components in the aerospace industry. The STC550’s precision and reliability are crucial for creating these specialized parts that ensure the safety and performance of aircraft.

The medical equipment industry also benefits from the STC550 lathe, as it offers the necessary precision and versatility for manufacturing medical components. The mold manufacturing sector utilizes the lathe for creating precision molds with intricate details. Additionally, the electronic industry, optical equipment sector, and metal processing field can leverage the STC550’s capabilities for a wide range of applications.

The STC550 horizontal slant bed lathe with its straight-line tool holder is well-suited for processing small and precision workpieces in various industries. Its applications span across automobile manufacturing, aerospace, medical equipment, mold manufacturing, electronics, optical equipment, and metal processing. By utilizing the STC550 lathe, manufacturers in these industries can achieve accurate and high-quality results, meeting the specific demands of their respective sectors.

6. About HAISHU Machinery

As the professional CNC machine designer and manufacturer, Taian HAISHU Machinery Co., Ltd (Haishu Machinery) is the high-tech enterprise specialized in CNC machine development, production, sales and service since 2001. We have more than 30 professional talented CNC experts and more than 12,000 square meters manufacturing factory. Our high quality and innovative products include CNC lathe, CNC milling machine, CNC machining center, CNC turn-mill machine, CNC tool grinding machine, CNC pipe threading lathe, CNC wood lathe, stone CNC machine, CNC root canal file grinder and custom CNC equipment for special requirements.

HAISHU Machinery is not only manufacturing best quality CNC machine products but also providing custom product design and after sale services. Welcome, contact us for detailed information.