The basic components of CNC machine tools include machining program carriers, numerical control devices, servo drives, machine tool bodies and other auxiliary devices. The basic working principle of each component is outlined below.

Processing program carrier

When the CNC lathe is working, it is not necessary for the worker to directly operate the machine tool. To control the CNC machine tools, the machining program must be programmed. The part processing program includes the relative motion trajectory of the tool and the workpiece on the machine tool, the process parameters (feedrate spindle speed, etc.) and auxiliary motion. The part processing program is stored in a program carrier, such as a punched paper tape, a cassette tape, a floppy disk, etc., with a certain format and code, and the program information is input to the CNC unit through the input device of the numerical control machine tool.

CNC device

The numerical control device is the core of the CNC machine tools. Modern numerical control devices are all in the form of CNC (Computer Numerical Control). This CNC device generally uses multiple microprocessors to implement numerical control functions in the form of programmed software. Therefore, it is also called Software NC. The CNC system is a position control system that interpolates the ideal motion trajectory based on the input data and outputs it to the parts required to machine the actuator. Therefore, the numerical control device mainly consists of three basic parts: input, processing and output. All of this work is reasonably organized by the computer’s system program, allowing the entire system to work in harmony.

1) Input device: The numerical control command is input to the numerical control device, and according to different program carriers, there are different input devices. There are mainly keyboard input, disk input, CAD/CAM system direct communication mode input and DNC (direct digital control) input to the upper computer. There are still many systems that still have the paper tape input form of the optical reader.

(1) Paper tape input method. The paper tape photoelectric reader can be used to read the part program, directly control the movement of the machine tool, or read the contents of the paper tape into the memory, and control the movement of the machine tool by using the part program stored in the memory.

(2) MDI manual data input method. The operator can use the keyboard on the operation panel to input the instructions of the machining program, which is suitable for relatively short programs.

In the control device edit state (EDIT), the machining program is input into the memory and stored in the memory of the control device. This input method can be used repeatedly. This method is generally used for manual programming.

On the numerical control device with session programming function, different menus can be selected according to the prompts on the display, and the machining program can be automatically generated by inputting the relevant size numbers by means of human-machine dialogue.

The DNC direct numerical control input mode is adopted. The part program is saved in the upper computer, and the CNC system receives the subsequent block from the computer while processing. The DNC method is mostly used for complex workpieces designed with CAD/CAM software and directly generates part programs.

2) Information processing: the input device transmits the processing information to the CNC unit, and compiles it into a piece of computer-recognizable information. The information processing part gradually stores and processes the information according to the control program, and then sends the position and speed command to the servo through the output unit. System and main motion control section. The input data of the CNC system includes contour information of the part (starting point, end point, straight line, arc, etc.), machining speed and other auxiliary machining information (such as tool change, shifting, coolant switch, etc.). The purpose of data processing is to complete the insertion. Preparation before the complement operation. The data processing program also includes tool radius compensation, speed calculation, and processing of auxiliary functions.

3) Output device: The output device is connected to the servo mechanism. The output device receives the output pulse of the arithmetic unit according to the command of the controller, and sends it to the servo control system of each coordinate, and drives the servo system through power amplification, thereby controlling the machine tool to move according to the specified requirements.

Servo and measurement feedback system

The servo system is an important part of the CNC machine tools, which is used to realize the feed servo control and spindle servo control of CNC machine tools. The function of the servo system is to accept the command information from the numerical control device, and then convert it into linear displacement or angular displacement motion of the machine tool by power amplification and shaping. Since the servo system is the last link of the CNC machine tools, its performance will directly affect the technical indexes such as the precision and speed of the CNC machine tool. Therefore, the servo drive device of the CNC machine tools is required to have good fast response performance, and accurately and sensitively track the numerical control device. The digital command signal is sent and the instructions from the numerical control device can be faithfully executed to improve the dynamic follow-up characteristics and static tracking accuracy of the system.

The servo system consists of two parts: the drive unit and the actuator. The drive unit is composed of a spindle drive unit, a feed drive unit, a spindle servo motor, and a feed servo motor. Stepper motors, DC servo motors and AC servo motors are commonly used drives.

The measuring component detects the actual displacement value of each coordinate axis of the CNC machine tools and inputs it into the numerical control device of the machine tool through the feedback system. The numerical control device compares the actual displacement value returned by the numerical control device with the command value and outputs the set value to the servo system. The required displacement command.

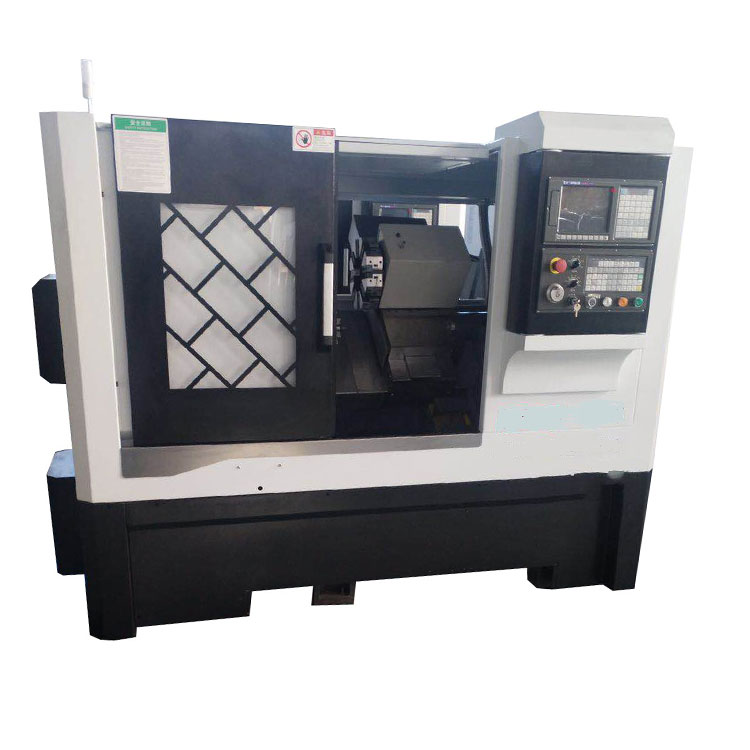

Machine body

The machine host is the main body of the CNC machine. It includes mechanical components such as bed, base, column, beam, slide, table, headstock, feed mechanism, tool holder and automatic tool changer. It is the mechanical part that automatically performs various cutting operations on CNC machine tools. Compared with traditional machine tools, the main body of CNC machine tools has the following structural features:

1) Adopt a new machine tool structure with high rigidity, high shock resistance and small thermal deformation. Generally, the stiffness and shock resistance of the machine tool main body are improved by improving the static stiffness of the structural system, increasing the damping, adjusting the quality of the structural member and the natural frequency, so that the machine tool body can adapt to the need for the CNC machine tool to continuously and automatically perform the cutting process. Measures such as improving machine structure layout, reducing heat generation, controlling temperature rise, and using thermal displacement compensation can reduce the impact of thermal deformation on the machine tool host.

2) The high-performance spindle servo drive and feed servo drive are widely used to shorten the drive chain of CNC machine tools and simplify the structure of the machine tool drive system.

3) Adopt high transmission efficiency, high precision, gapless transmission and moving parts, such as ball screw nut pair, plastic sliding guide, linear rolling guide, static pressure guide and so on.

CNC machine tool auxiliary device

The auxiliary device is the necessary device to ensure the full play of the functions of the CNC machine tool. The commonly used auxiliary devices include: pneumatic, hydraulic device, chip removal device, cooling, lubrication device, rotary table and numerical control indexing head, protection, lighting, etc. Auxiliary device

About HAISHU Machinery

Taian Haishu Machinery Co., Ltd. is the professional CNC machine designer and manufacturer dedicated in supplying automobile wheel production and repair solutions to worldwide customers. We have been always worked hard to become the leader in designing and manufacturing CNC lathes since 2001. We have more than 30 talented experts and more than 12,000 square meters factory. Our innovative, high-quality products include wheel CNC machine, wheel repair machine, brake drum lathe and customized CNC lathe machine.